Every self-respecting professional or company has some tricks up his sleeve and if the market does not offer them, someone has to come up with that. This happens because, every tool you work with has been developed to face specific situations, in specific contexts. This is the reason why, if necessary, a companies or a professionals prefers to create and recreate the tools they use by sewing them on their own needs.

This is why we created CIRo 13.

Our tools are our best allies to reduce times and mitigate errors; which is why we prefer to create prototypes that live up to our work rather than relying on frozen prefabricated solutions. solutions, often below our expectations.

Think about it; which chef would have someone else prepare their favorite dish?

Our leitmotif starts from this, from the uniqueness we love to give to our products and from the exclusivity we offer our customers. Surely you know that famous saying: “if you want something done, do it yourself!”. For this reason we created CSV2ALL, Cloud Designer, SeziCo, CiRo 13 and many more.

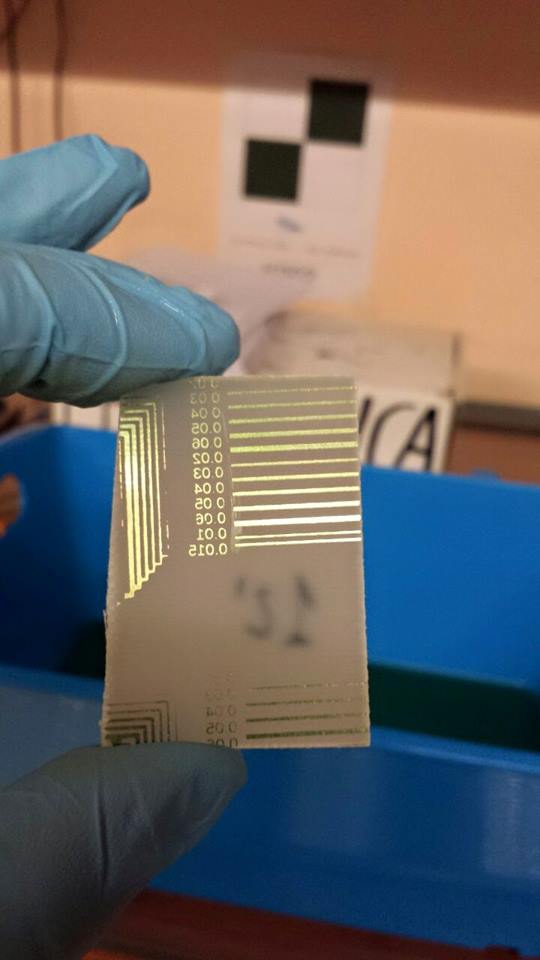

The latter represented a real challenge in the field of high-precision robotics. He’s the result of many sleepless nights and caffè. The story of CiRo 13 begins in 2016, on a January evening we began to imagine it, outlining the profile of what it would become: an indispensable robot in our laser scanning work, capable of giving us photorealistic colors and the best accuracy that we had never seen before.

In the span of two years of preparation and study, several prototypes followed one another. At last, prototype number 13 was a full success. The first step faced during the prototyping was to replace the gears of the first prototype with a belt. Then we decided to change the internal structure which initially involved the presence of a microcomputer while, around the eleventh model we opted for a microcontroller.

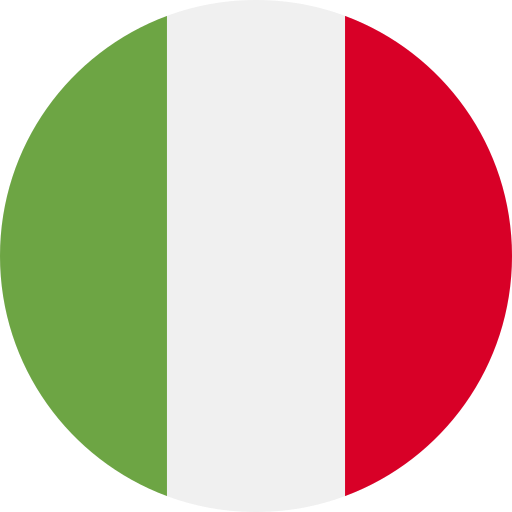

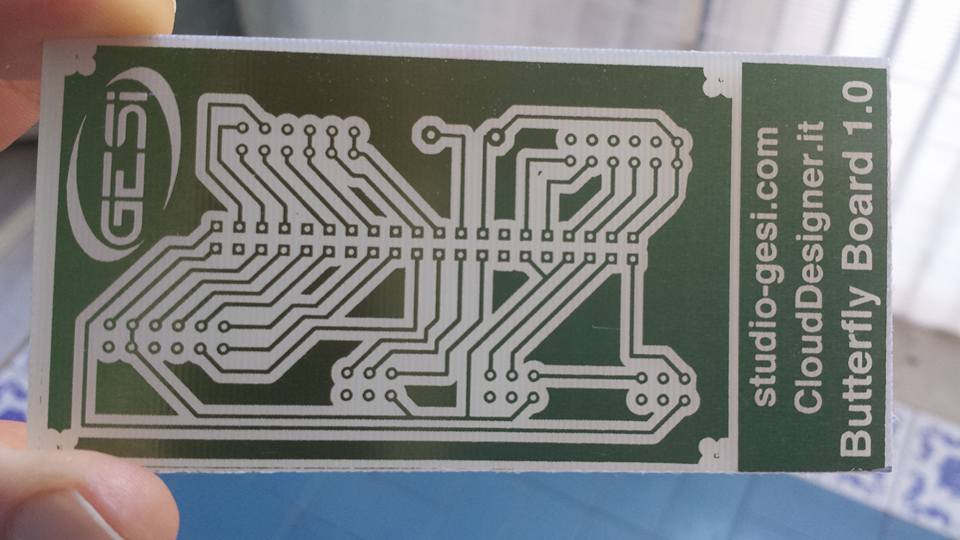

In all CiRo 13 prototypes, internal components such as boards were photoetched, perforated and hand soldered in house. In the thirteenth prototype, visual devices have also been added, in order to make the final product more industrial: photoetch, drilling, programming, thermal connections. This is how CiRo 13 acquired its dazzling ready-to-use appearance!

The evolution of CiRo 13 went through several stages before it was really ready and, even today, we continue to study possible improvements.

The robot has been designed with everything in mind. We have even preserved the wear of the internal components, carefully choosing the acceleration movements, preferring bilinear or trapezoidal accelerations for Ciro 13 avoiding hard blows to the heart of the machine.

Among the studies carried out during the adaptation of the mechanical structure, however, there are the calibration of the camera and the angular compensations.

CiRo 13 is one of our first prototypes, with him we have increased our skills in advanced robotics and in its improvement we have laid the foundations for the development of sophisticated robots, open to different fields of use.

The passion for our work, the dedication to our tools and the belief that everything is perfectible, push us to always give our best.

If you are curious to follow the evolution of our work by taking a look at the other articles about our “creatures”, you can also read: GPS: a software to solve accuracy errors and more.

If you are interested in our CiRo 13, do not waste any time, contact us immediately, we will answer all your questions.